On-site Examination

Recording and evaluating existing structures and accompanying the planning of new facilities with a solid as-is survey

Two sides of the same coin – examination and aerotechnical survey

Even though both services overlap in most cases, we differentiate here in the depth and breadth of the information collected. Both are part of a solid basis for planning and optimising an air handling system.

Examinating on site

A look at the structures that have grown and the new requirements

The greatest constant is change. Industrial companies often have structures and production facilities that have evolved over decades. If production requirements or legal regulations (hazardous substance limits, energy consumption) change, adjustments to technical infrastructures (retrofits) are usually also necessary.

The same questions arise again and again:

Which facilities are available and in what condition?

Which old systems can still be usefully reused?

What optimisation measures are required and how motivated?

Which systems (parts) need to be replaced or retrofitted in order to meet new legal requirements or the voluntary commitment to save energy costs in the future?

Based on a solid analysis of all installations and conditions on site, a structured overview of all necessary changes is obtained. This is the basis for target-oriented recommendations for action.

What we offer you

Our range of services:

- We prepare the measurements and drawings of the air handling equipment if no as-built or revision plans are available (pipework plans and system diagrams).

- We check the as-built plans (if available) including a detailed target/actual analysis, measurement of air volume flows and pressures and comparison of the target/actual values.

- We provide a general assessment of the condition of the ventilation systems (state of execution, dimensioning…) as well as the individual components.

- We analyse and evaluate the function of the current measurement and control technology (M&C) and take into account, for example, production specifications, mode of operation and simultaneities.

Aerotechnical survey on-Site

Using analyses, methods and experience to gain important insights and key figures

No planning without regarding the ACTUAL status. In the course of expansions or conversions in production, the requirements and often also the spatial conditions change around questions of ventilation technology.

- Are there new, additional emission sources with corresponding material and/or thermal loads?

- Are production lines being converted and do the spatial arrangements change?

- Is a production-hall being converted and how does this affect existing ventilation concepts?

These questions require a reassessment of the overall situation. On the basis of the knowledge gained, optimisation and modification measures can be determined more precisely, and the basic key figures determined by us also form the basis for more extensive planning services.

Our services at a glance

Aerotechnical survey on-Site

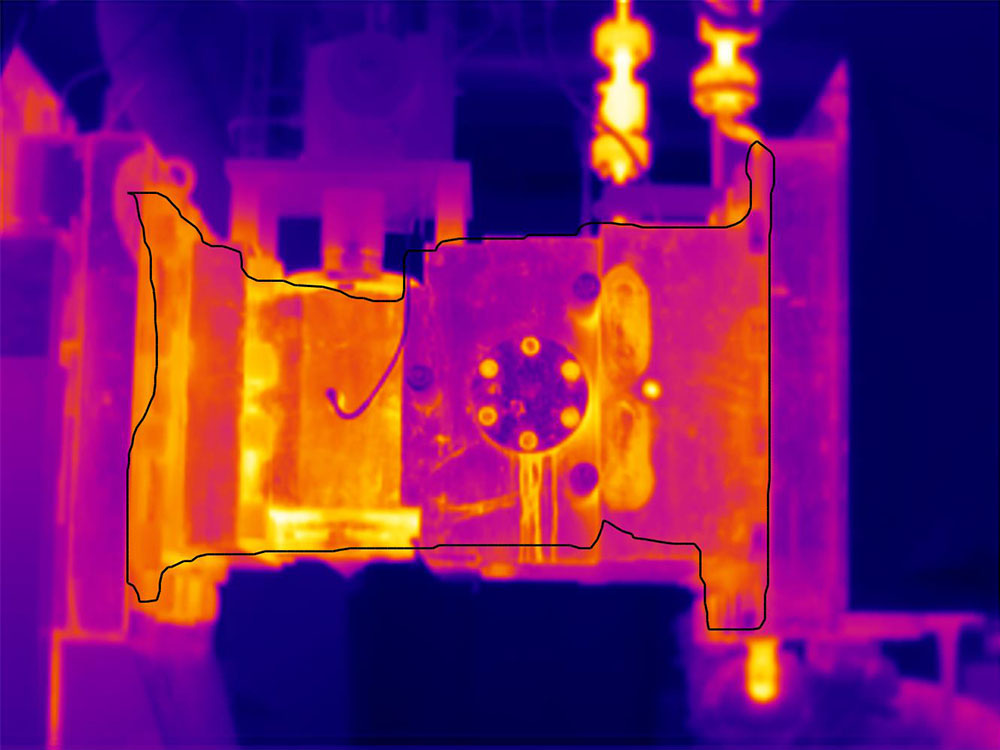

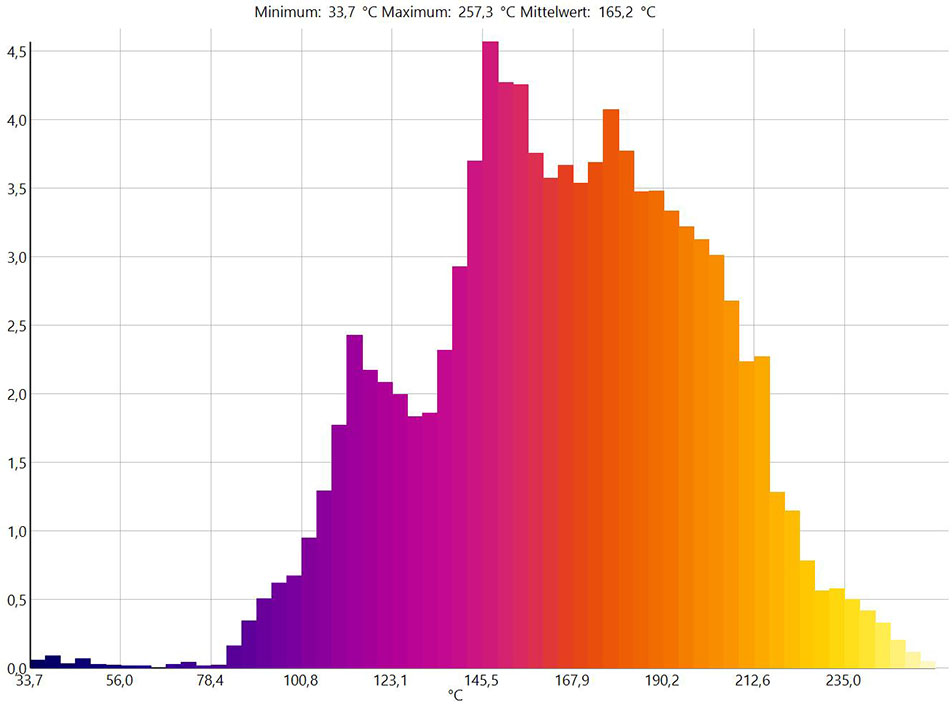

- We determine and evaluate all relevant emission sources (material and thermal), taking into account load factors and simultaneities.

- We determine the boundary conditions of the emission-relevant situations and processes.

- We determine and document disturbing influences such as cross-flows, e.g. by visualisation using artificial fog.

- We measure the decisive ventilation parameters such as air volumes, pressures and velocities in all supply and extract air ducts.

Concept development for the optimisation / supplementation of the existing plants

- Checking the performance of existing installations with regard to demand (comparison with the actual emission volume flows generated).

- We adapt existing installations to the actual demand or replace them with aerodynamically optimised components.

- Together with you, we agree on the optimal installation location for ventilation components.

- We optimise and dimension the supply air technology with preference for the “stratified flow” system.

Summary in a new, sustainable overall air and energy technology concept

- We prepare a comprehensive concept description with all basic key figures required for further planning.

- We determine budgets for the implementation of our concepts (also for sensible sub-sections).